You drive on it every day. Your water flows through it. Your electricity travels over it.

Heavy civil construction builds the backbone of modern life. But most people don’t know what it really means. I’ve watched bridges go up from nothing. I’ve seen whole highway systems get built. This guide will teach you about heavy civil construction.

You’ll learn what projects count as heavy civil work. You’ll see the big companies that shape our world. I’ll show you how construction works from start to finish.

Here’s what you’ll find:

What types of projects count as heavy civil construction, which companies you should know about, how the construction process works step by step, what problems these projects face today, new technologies that are changing things, how sustainability affects the future, what jobs pay and what they require, real examples from big projects.

No hard words. No confusing terms. Just simple facts from someone who’s done this work.

If you want a career change, think about investing in construction, or just want to know how roads get built, you’ll get clear answers here.

What Falls Under Heavy Civil Construction?

Infrastructure Projects That Shape Our World

Roads and highways: The arteries of commerce. Every mile of asphalt connects cities and towns. Interstate highways move goods across the country.

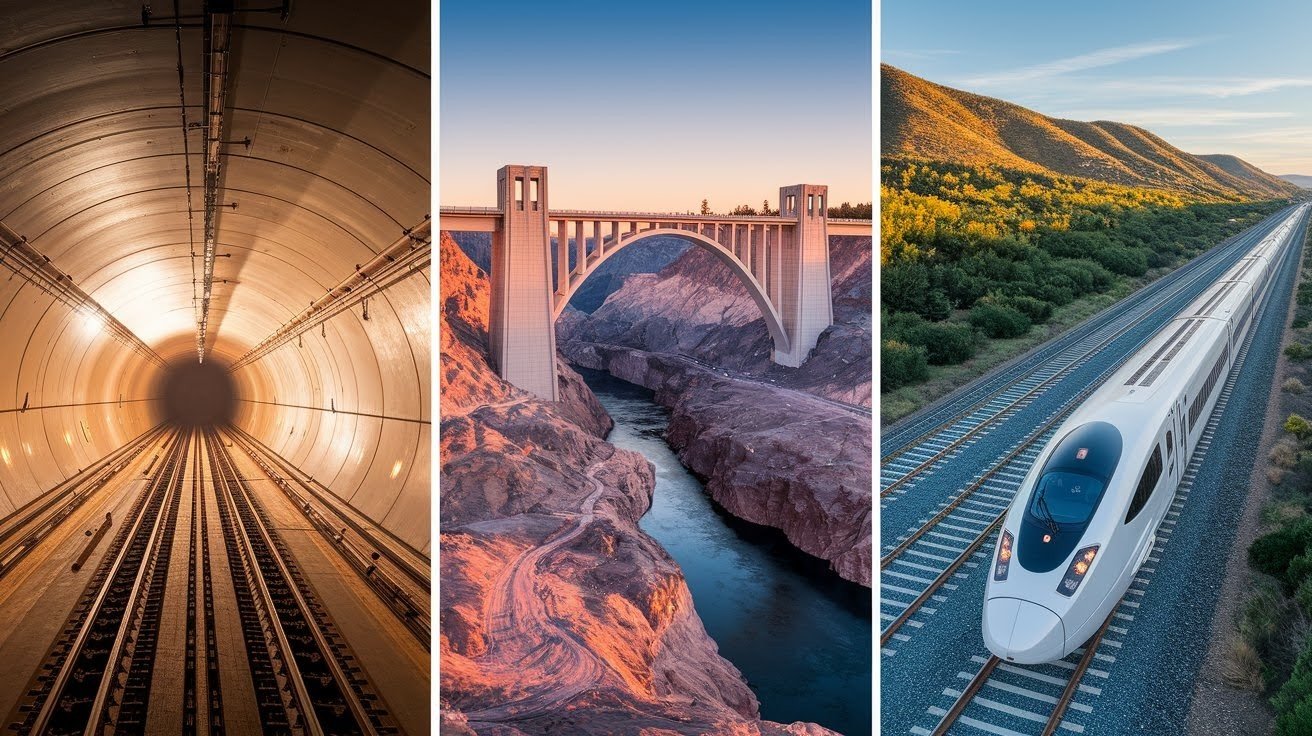

Bridges and tunnels: Connecting communities. These structures span rivers and mountains. They make travel possible where geography blocks the way.

Water treatment plants: Clean water for millions. These facilities remove dirt and germs from our drinking water. They keep families healthy every day.

Sewage systems: Hidden but vital. Underground pipes carry waste away from homes. Treatment plants clean the water before sending it back to rivers.

Airports and runways: Gateways to the world. Massive concrete runways support jumbo jets. Terminal buildings handle millions of passengers each year.

Utility Construction Projects

Power plants and substations make electricity for homes and businesses. Gas pipelines carry fuel across thousands of miles. Telecommunications towers connect our phones and internet.

Solar and wind farms generate clean energy. These projects fight climate change while powering our cities.

Heavy Industrial Construction

Manufacturing facilities produce cars, electronics, and food. Chemical plants make plastics and medicines. Mining operations dig up coal, gold, and other materials.

Port facilities handle cargo ships from around the world. Massive cranes move containers from ships to trucks.

Here’s what surprises most people about heavy civil construction – it touches every part of your life without you noticing.

Key Players in the Heavy Civil Construction Industry

The Big Names You Should Know

Bechtel Corporation: Global infrastructure giant. This company builds nuclear plants and major highways. They’ve worked in over 160 countries.

Fluor Corporation: Engineering powerhouse. They design and build refineries and chemical plants. Government contracts make up much of their work.

Kiewit Corporation: Railroad to skyscrapers. Started in 1884 building railroads. Now they build everything from bridges to data centers.

AECOM: Design meets construction. They plan cities and build them too. Environmental cleanup is another specialty.

Specialized Contractors

Earthmoving specialists move millions of tons of dirt. They shape the land before building starts. Concrete contractors mix and pour foundations.

Steel erection companies build the skeleton of structures. Utility installers run power lines and water pipes.

Government Agencies

The Department of Transportation plans and funds highway projects. Army Corps of Engineers builds dams and flood control systems.

Local public works departments maintain roads and sewers.

The Construction Process: From Planning to Execution

Phase 1: Planning and Design

Site surveys: Know your ground. Engineers measure every inch of land. They map elevation changes and soil types.

Environmental impact studies check how projects affect wildlife. Permit acquisition can take months or years. Budget development sets spending limits.

Phase 2: Pre-Construction

Soil testing: Foundation for success. Bad soil means unstable buildings. Testing prevents costly mistakes later.

Utility location and marking prevents accidents. Material procurement secures steel, concrete, and equipment. Equipment mobilization brings heavy machinery to the site.

Phase 3: Construction Execution

Site preparation and clearing removes trees and old buildings. Excavation and grading shapes the land. Foundation work creates a solid base.

Structure assembly puts everything together. Final inspections make sure work meets safety standards.

Most projects take 2-5 years from start to finish. Weather delays happen often. Coordination between teams matters most.

Challenges Facing Heavy Civil Construction Projects

Financial Problems

Rising material costs: Steel up 40% since 2020. Inflation hits construction harder than other industries. Labor shortages drive wages higher.

Equipment rental prices keep climbing. Project financing gets harder as interest rates rise.

Technical Challenges

Aging infrastructure needs replacement now. Many bridges are 50+ years old. Complex soil conditions surprise engineers.

Weather delays cost time and money. Coordination problems between multiple contractors create headaches.

Regulatory Obstacles

Environmental compliance adds time to every project. Safety regulations require extensive training. Permit delays can stretch for years.

Community opposition stops some projects completely. Local politics affect construction decisions.

Modern Technologies Changing Heavy Civil Construction

Digital Tools

3D modeling software: Build it twice, once digitally. Engineers spot problems before construction starts. This saves millions in mistakes.

Drone surveying and monitoring tracks progress from above. GPS-guided equipment places materials with perfect accuracy. Real-time project tracking keeps everyone informed.

Advanced Materials

High-performance concrete lasts longer than old mixes. Composite materials resist weather and wear. Smart sensors embedded in structures monitor stress and damage.

Self-healing concrete, Yes, it’s real. Special bacteria in the concrete fills cracks automatically.

Automation and Robotics

Autonomous construction vehicles work without drivers. Robotic welding systems work faster than humans. Automated material handling moves supplies efficiently.

3D printing creates components in factories. Quality stays consistent every time.

Some highway projects now use robots to lay asphalt at night. They work when traffic is lightest.

Sustainability and the Future of Heavy Civil Construction

Green Building Practices

Recycled materials: Old roads become new ones. Concrete gets crushed and reused. This cuts waste and saves money.

Energy-efficient designs reduce power consumption. Stormwater management systems prevent flooding. Native plant landscaping needs less water.

Climate Adaptation

Flood-resistant infrastructure protects communities. Heat-resistant materials handle extreme temperatures. Renewable energy integration reduces carbon emissions.

Carbon capture technology in concrete removes CO2 from the air. This helps fight climate change.

Circular Economy Principles

Material reuse strategies reduce waste streams. Waste reduction techniques save money and resources. Life-cycle cost analysis considers long-term impacts.

End-of-life planning prepares for eventual replacement. This thinking changes how we build today.

Career and Industry Outlook

High-Demand Jobs

Project managers: The conductors of construction. They coordinate teams and timelines. Leadership skills matter more than technical knowledge.

Civil engineers design safe structures. Heavy equipment operators run massive machines. Construction superintendents oversee daily work.

Skills That Pay

Technical expertise opens doors to better jobs. Problem-solving abilities help when things go wrong. Safety certification – You can’t work without it.

Leadership experience leads to management roles. Communication skills help teams work together.

Salary Expectations

Entry-level positions start at $45,000-$60,000 per year. Mid-career workers earn $70,000-$100,000 annually. Senior roles pay $120,000 or more.

Specialized skills command higher pay. Crane operators and welders earn premium wages.

Industry Growth Projections

7% growth expected through 2032. That’s faster than most industries. $2.6 trillion infrastructure need creates opportunities.

Baby boomer retirements open positions for younger workers. Good timing for career changes.

Case Studies: Notable Heavy Civil Construction Projects

Success Story 1: The Big Dig (Boston)

Challenge: Relocate I-95 underground through downtown Boston. The old elevated highway blocked the city’s growth.

Timeline: 16 years of construction from 1991 to 2007. Cost: $14.6 billion, making it America’s most expensive highway project.

Lesson learned: Planning prevents disasters. Poor early planning caused massive cost overruns.

Success Story 2: Hoover Dam Bypass Bridge

Engineering marvels in harsh desert conditions. Workers faced 120-degree heat and strong winds. Completed ahead of schedule in 2010.

Earthquake-resistant design protects against natural disasters. Economic impact brought jobs and tourism to the region.

Success Story 3: California High-Speed Rail

Ongoing project: Lessons in real-time. Environmental challenges require special wildlife crossings. Political problems change funding and timelines.

Technology innovations include earthquake-resistant tracks. The project teaches the industry new methods.

Every project teaches the industry something new. Mistakes become lessons for future work.

Conclusion

Heavy civil construction shapes every part of your daily life. You now understand what makes this industry tick. The projects range from highways to power plants. The companies behind them employ millions of people.

Technology is changing everything from planning to execution.

Sustainability drives the future of construction. Green materials and smart designs become standard practice. Climate-resistant infrastructure protects communities for decades.

Career opportunities are everywhere. Project managers earn six figures. Equipment operators stay in high demand. Engineers design the cities of tomorrow. Every bridge you cross started as someone’s vision.

Every road you travel required massive coordination. Skilled builders made it happen.

The industry needs fresh talent. Infrastructure investment continues growing. Your community depends on these workers.

Think about your role in shaping America’s foundation. If you want a career path or investment opportunity, heavy civil construction builds the world we live in.

The future starts with the next project.

Frequently Asked Questions

What’s the difference between heavy civil construction and regular construction?

Heavy civil construction builds large-scale infrastructure like highways, bridges, and power plants. Regular construction focuses on buildings like homes, offices, and retail stores.

How long do heavy civil construction projects typically take?

Most projects run 2-5 years from planning to completion. Complex projects like major highway systems can take 10-15 years due to environmental studies and permit requirements.

What education do you need for heavy civil construction careers?

No college degree required for many positions like equipment operators and laborers. Engineering and project management roles typically need a 4-year degree in civil engineering or construction management.

Why do heavy civil construction projects cost so much money?

Projects use massive amounts of materials like concrete, steel, and asphalt. Labor costs are high due to skilled worker shortages, and projects often face unexpected soil or environmental challenges.

What’s the biggest challenge facing the heavy civil construction industry?

Skilled worker shortage tops the list of industry concerns. Many experienced workers are retiring, and fewer young people are entering construction trades despite good pay and job security.