Your driveway takes a beating every single day. Cars, trucks, weather, and time all work against it. But here’s the thing – most driveway problems come from one mistake: wrong thickness.

Too thin? You’ll see cracks within months. Too thick? You’ve wasted money on concrete you didn’t need. Getting it right means your driveway lasts decades instead of years.

This guide covers everything you need to know about driveway thickness. We’ll show you:

- How thick your specific driveway should be

- What factors affect thickness decisions

- How to avoid costly mistakes

- When to hire professionals versus doing it yourself

I’ve helped homeowners make smart driveway decisions for over 15 years. The advice here comes from real projects and real results – not theory from a textbook.

By the end, you’ll know exactly how thick to make your driveway. No guesswork. No expensive do-overs. Just a solid foundation that protects your investment for decades to come.

Understanding Concrete Driveway Thickness

What Does “Thickness” Mean in Concrete Driveways?

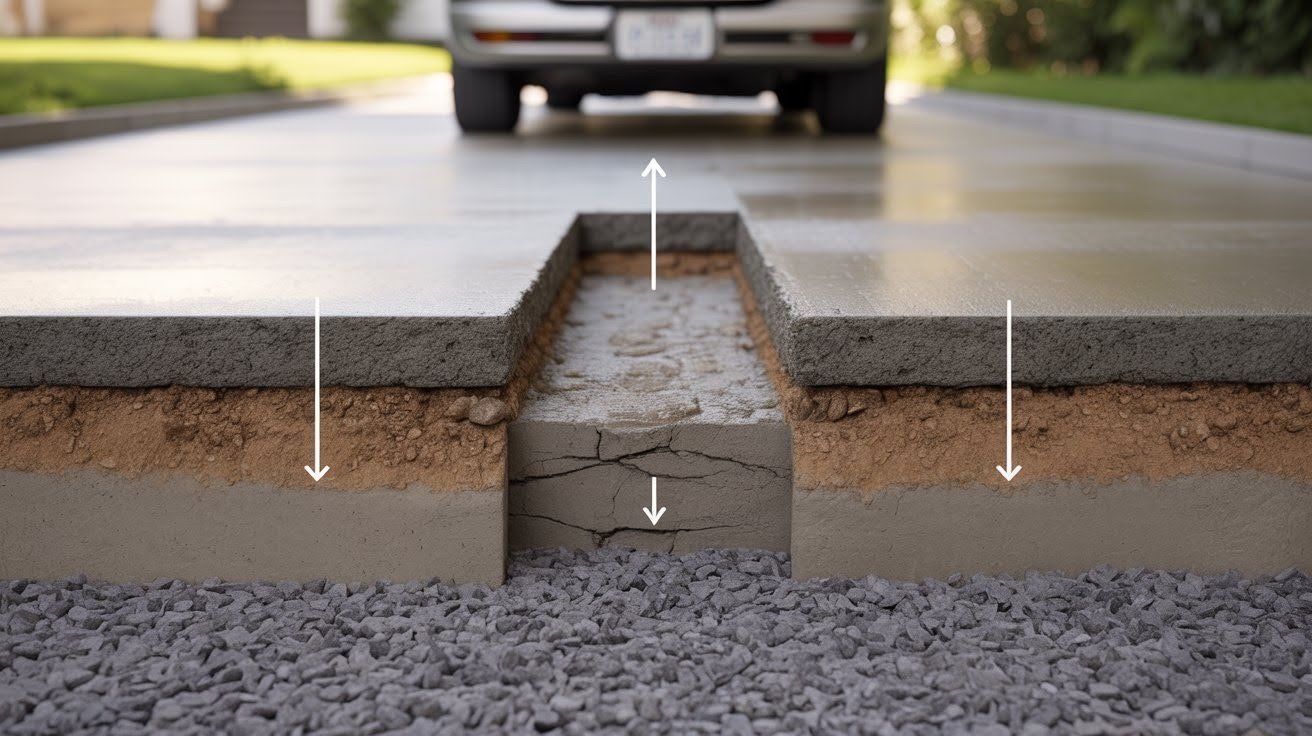

When contractors talk about driveway thickness, they’re referring to how deep your concrete slab will be. This measurement runs from the top surface down to the prepared base underneath. Think of it like the depth of a cake – except this cake needs to support thousands of pounds.

Thickness directly controls how much weight your driveway can handle without cracking or sinking. A thicker slab spreads weight over a larger area, reducing pressure on any single spot. This makes your driveway stronger and helps it last longer.

The thickness also determines how well your driveway handles freeze-thaw cycles. Thinner concrete cracks more easily when water freezes inside small gaps. Proper thickness gives your driveway the strength to resist these natural forces year after year.

Standard Recommendations

Most residential driveways work perfectly fine with 4 inches of concrete thickness. This handles regular cars, small trucks, and typical family vehicles without problems. Four inches has become the standard because it balances cost with performance for most homeowners.

However, some situations call for thicker concrete. If you park heavy trucks, RVs, or commercial vehicles, consider 5-6 inches minimum. Poor soil conditions, areas with harsh winters, or high-traffic driveways also benefit from extra thickness. The additional cost upfront saves you from expensive repairs later.

Remember that local building codes might set minimum requirements. Always check with your city before starting any concrete work.

Factors That Determine Ideal Driveway Thickness

1. Vehicle Weight and Load

The weight of vehicles using your driveway plays a huge role in determining proper thickness. Regular passenger cars typically weigh 3,000-4,000 pounds. Standard 4-inch concrete handles this weight easily without stress or damage.

Heavy trucks, RVs, and work vehicles change everything. A loaded pickup truck can weigh 8,000 pounds. Large RVs often exceed 15,000 pounds. These heavier loads create intense pressure points that can crack thin concrete.

When heavier vehicles use your driveway regularly, the concrete experiences repeated stress cycles. Each time a heavy vehicle parks or drives over the same spot, it pushes down on the concrete. Over time, this repeated loading weakens the slab and leads to cracking or settling.

2. Soil Type and Stability

Your driveway’s foundation – the soil underneath – matters just as much as the concrete itself. Stable, well-draining soil provides excellent support for standard thickness concrete. Clay soils and loose fill create problems.

Expansive clay soils shrink and swell with moisture changes. This movement puts stress on concrete from below, causing cracks and uneven settling. Sandy soils may not provide enough support, allowing concrete to sink under heavy loads.

Poor soil conditions often require thicker concrete to compensate for weak support. Some contractors also recommend soil stabilization or improved base preparation when working with problematic ground conditions.

3. Climate and Weather Conditions

Weather patterns in your area directly affect how thick your driveway should be. Freeze-thaw cycles create the biggest problems for concrete driveways in colder climates.

When water gets into small cracks and freezes, it expands with tremendous force. This expansion widens cracks and can split concrete apart. Thicker concrete resists this damage better than thin slabs.

Hot climates create different challenges. Concrete expands in heat and contracts when temperatures drop. Moisture from rain and humidity also affects concrete performance. Areas with extreme temperature swings or heavy precipitation often benefit from extra thickness.

4. Driveway Usage

How often vehicles use your driveway affects thickness requirements. A retired couple with one car creates minimal stress on their concrete. A busy family with multiple vehicles, frequent deliveries, and regular visitors puts much more wear on their driveway.

Commercial driveways face even greater demands. Delivery trucks, customer traffic, and business vehicles create constant loading cycles. These high-use situations typically require 5-6 inches minimum thickness.

Consider your household’s specific usage patterns. Do you have teenagers who bring friends over frequently? Do you run a business from home? Do delivery services use your driveway daily? Higher usage means you should consider thicker concrete for better long-term performance.

Signs Your Driveway May Need More Thickness

Common Warning Signs

Your driveway sends clear signals when it’s struggling with inadequate thickness. Hairline cracks that appear within the first few years often indicate the concrete is too thin for the loads it’s carrying. These cracks typically start small but grow wider and longer over time.

Settling creates another obvious red flag. If sections of your driveway sink or become uneven, the concrete may lack the strength to distribute weight properly. You’ll notice dips where heavy vehicles park regularly or areas that seem lower than the rest of the surface.

Edge erosion along the sides of your driveway also suggests thickness problems. When concrete edges crumble or break away, it often means the slab doesn’t have enough mass to handle the stress. Poor drainage makes this worse by washing away supporting material from underneath.

Surface damage like spalling – where the top layer chips or flakes off – can indicate the concrete is working too hard. While some surface wear is normal after many years, early damage suggests the slab is overstressed for its thickness.

When to Upgrade or Replace

Multiple cracks across your driveway signal it’s time for replacement with proper thickness. If you’re patching the same areas repeatedly, the underlying problem likely stems from inadequate concrete depth.

Major settling that creates trip hazards or drainage problems requires complete replacement. Simply patching settled areas doesn’t fix the root cause – insufficient thickness to handle the loads.

When replacing a failed driveway, consider what caused the original problems. If you’ve added heavier vehicles to your household or noticed the damage occurred quickly, plan for increased thickness in the new installation. Most failed driveways benefit from at least one additional inch of concrete depth to prevent repeat problems.

The Role of Concrete Mix and Reinforcement

Choosing the Right Concrete Mix

The concrete mix you choose affects your driveway’s strength just as much as thickness does. Most residential driveways need concrete with 3000-4000 psi compressive strength. This rating tells you how much pressure the concrete can handle before it fails.

Lower strength concrete costs less but won’t last as long under heavy loads. Higher strength mixes provide better durability but increase your project cost. For most homeowners, 3500 psi offers the best balance of performance and price.

Well-graded aggregates – the rocks and sand mixed into concrete – create a stronger finished product. Good aggregates fill spaces efficiently and bond well with cement. Your concrete supplier should use properly sized materials that meet local standards.

Air entrainment adds tiny air bubbles to the concrete mix. These bubbles give water somewhere to go when it freezes, reducing crack damage. If you live in a climate with freeze-thaw cycles, make sure your concrete includes air entrainment additives.

Using Reinforcement Materials

Steel reinforcement helps concrete handle stress better, especially tension forces that cause cracking. Two main options exist: rebar and wire mesh. Each has specific advantages depending on your situation.

Rebar consists of steel bars placed in a grid pattern before concrete gets poured. It provides excellent strength and works well for heavy-duty applications. Rebar costs more and takes longer to install, but it significantly improves concrete performance under heavy loads.

Wire mesh offers a simpler, less expensive reinforcement option. The mesh gets rolled out over the prepared base and held in position during concrete placement. While not as strong as rebar, wire mesh still helps control cracking in residential applications.

Steel reinforcement becomes essential for certain situations. Heavy vehicle loads, poor soil conditions, or areas with extreme weather typically require some form of reinforcement. Even standard driveways benefit from reinforcement in high-stress areas like where vehicles turn or park regularly.

Preparing for a Durable Concrete Driveway Installation

Site Preparation

Proper site preparation makes the difference between a driveway that lasts decades and one that fails within years. The work that happens before concrete gets poured determines how well your finished driveway performs.

Grading creates the right foundation for your concrete. The ground needs to be level and properly sloped to direct water away from your home. Poor grading leads to water pooling, which weakens concrete and causes premature cracking.

Subbase compaction provides crucial support for your concrete slab. Loose soil under concrete will settle over time, creating voids that cause cracking and uneven surfaces. Professional contractors use compaction equipment to create a solid, stable base that won’t shift.

The subbase material itself matters too. Most contractors use crushed stone or gravel that drains well and compacts firmly. This layer typically runs 4-6 inches thick and gets compacted in lifts to achieve maximum density.

Drainage design prevents water problems that destroy concrete driveways. Water needs somewhere to go when it hits your driveway surface. Proper slope directs runoff toward appropriate drainage areas. Without good drainage, water sits on concrete surfaces and seeps into cracks, causing freeze-thaw damage and erosion.

Why Professional Installation Matters

Local building codes set specific requirements for concrete driveways in your area. These codes cover thickness, reinforcement, drainage, and other technical details. Professional contractors know these requirements and ensure your project meets all regulations.

Permits often require professional installation or at least professional oversight. Many cities won’t issue permits for DIY concrete work because of safety and quality concerns. Using a licensed contractor streamlines the permit process and ensures code compliance.

DIY concrete projects carry significant risks that many homeowners underestimate. Concrete work requires specialized tools, proper timing, and technical knowledge. Mistakes in mixing, placing, or finishing concrete create expensive problems that are difficult or impossible to fix later.

Professional contractors also carry insurance that protects you from liability. If something goes wrong during installation, their coverage handles the costs. DIY projects leave you responsible for any damage or injuries that occur during construction.

Professional Installation Tips

- Get proper permits and use licensed, insured contractors only

- Schedule work during mild weather conditions for best results

- Clear access routes for concrete trucks and equipment

Site Preparation Essentials

- Test soil conditions and mark all utility lines before digging

- Create proper drainage slopes away from buildings

- Compact subbase thoroughly to prevent settling

- Install and brace edge forms securely

Quality Control Measures

- Order 3500-4000 psi concrete strength for residential use

- Add reinforcement in high-stress areas and poor soil conditions

- Maintain planned thickness throughout the pour

- Allow 7+ days curing time before driving on new concrete

Conclusion

Getting your driveway thickness right depends on several key factors: vehicle weight, soil conditions, climate, and usage patterns. Standard 4-inch concrete works for most residential situations, but heavier vehicles or challenging conditions require 5-6 inches or more.

Remember that proper thickness is just one piece of the puzzle. Quality concrete mix, reinforcement, and expert installation all contribute to long-term durability. Cutting corners on any of these elements can lead to expensive repairs down the road.

While thicker concrete costs more upfront, it’s a smart investment that pays off over decades. Consider consulting with experienced contractors who understand local conditions and building codes. They can help you make informed decisions that balance cost with performance.

A properly built driveway protects your investment and serves your family reliably for years to come. Take time to get it right the first time.

Frequently Asked Questions

How thick should my concrete driveway be for regular cars?

Most residential driveways need 4 inches of concrete thickness for standard passenger vehicles. This provides adequate strength for cars weighing 3,000-4,000 pounds without risk of cracking or damage.

Do I need thicker concrete if I park heavy trucks or RVs?

Yes, heavy vehicles require 5-6 inches minimum thickness to handle the extra weight safely. Large RVs and loaded trucks can weigh 15,000+ pounds, creating stress that standard thickness cannot handle.

Can I pour concrete directly on soil without preparation?

No, proper site preparation with compacted subbase is essential for driveway longevity. Pouring directly on unprepared soil leads to settling, cracking, and premature failure of your concrete.

What happens if my driveway concrete is too thin?

Thin concrete develops cracks within months and may settle unevenly under vehicle loads. These problems worsen over time and typically require complete replacement rather than simple repairs.

Should I attempt concrete driveway installation myself?

DIY concrete work carries significant risks including code violations, safety hazards, and costly mistakes. Professional contractors have the tools, knowledge, and insurance needed for proper installation that meets local requirements.