Removing a pool from your backyard isn’t as simple as draining the water and filling the hole. The costs can vary wildly depending on several factors you might not expect. This article breaks down the 11 main factors that affect pool removal costs.

You’ll get clear answers about what drives prices up or down. No more guessing or getting surprised by hidden fees.

Here’s what we’ll cover: pool type and size impact on pricing, access issues that increase labor costs, permit requirements in different areas, and disposal fees and material handling.

We’ve worked with hundreds of homeowners through pool removal projects. Our team has seen every situation from simple above-ground pools to complex in-ground installations. I’ve personally managed dozens of these projects and know where costs spiral out of control.

This experience helps us give you honest, realistic cost expectations. Stop wondering about pool removal costs. Get the facts you need to budget properly and choose the right contractor.

What Is the Ideal Concrete Driveway Thickness?

Getting the right thickness for your driveway saves you money and headaches down the road. Too thin, and you’ll deal with cracks and repairs. Too thick, and you’re wasting concrete and cash.

General Recommendation

For most homes, 4 inches of concrete works perfectly fine. This handles regular cars, minivans, and light pickup trucks without any problems.

But some situations call for more thickness:

- Clay or soft soils that shift and settle

- Areas with harsh freeze-thaw cycles

- Driveways on slopes or uneven ground

- Plans to occasionally park heavier vehicles

Consider 5 inches if any of these apply to your situation. The extra cost is minimal compared to fixing a cracked driveway later.

Go with 6 inches only when you know you need serious strength. This thickness handles most residential situations with room to spare.

Thickness for Heavy Loads

Some driveways need to handle serious weight on a regular basis. RVs, large trucks, boats on trailers, and work vehicles require stronger construction.

For these applications, start with 6 inches minimum. Add reinforcement like rebar or heavy-duty wire mesh. The concrete mix should be at least 4,000 PSI strength.

Commercial driveways or high-traffic areas might need even more. Consider 8 inches with proper reinforcement for constant heavy use.

Don’t try to save money on heavy-duty driveways. The repair costs far exceed the initial investment in proper thickness and materials.

Factors That Influence Concrete Thickness

Your driveway thickness isn’t a random choice. Several key factors determine what works best for your specific situation.

Type and Frequency of Vehicle Use

The vehicles you park and how often you use them make a big difference in thickness requirements.

A family car that drives over concrete twice a day creates much less wear than a delivery truck making daily stops. Even the same vehicle affects concrete differently based on usage patterns.

Consider these factors:

- Weight of your heaviest regular vehicle

- How many times per day you drive over the same spots

- Seasonal changes in vehicle use

- Future plans for different vehicles

Weight distribution matters too. A loaded pickup truck concentrates more force on the concrete than the same truck empty. Think about your typical usage, not just occasional situations.

Frequent use by heavy vehicles requires thicker concrete and better reinforcement. Occasional heavy loads can usually work with standard thickness if the base is solid.

Soil Conditions and Subbase

What sits under your concrete determines how much support it provides. Good soil means your concrete doesn’t have to work as hard.

Stable, well-draining soil creates an excellent foundation. Sandy soil with good compaction works well too. These conditions let you use standard thickness recommendations.

Problem soils require adjustments:

- Clay that swells when wet and shrinks when dry

- Loose fill dirt that hasn’t settled completely

- Areas with poor drainage that stay soggy

- Soil with organic matter that decomposes over time

Weak or shifting soils need thicker concrete to bridge over problem areas. Sometimes fixing the soil costs less than adding concrete thickness. A soil engineer can help you decide the best approach.

Local Climate

Your area’s weather patterns affect how concrete performs over years of use.

Freeze-thaw cycles create the biggest problems. Water gets into tiny cracks, freezes, expands, and makes bigger cracks. Areas with frequent temperature swings around freezing need extra protection.

Moisture also plays a role. Heavy rainfall can saturate the subbase and reduce support. Hot, dry climates cause different expansion and contraction patterns.

Consider your local conditions:

- Average number of freeze-thaw cycles per year

- Typical rainfall amounts and drainage

- Temperature extremes and daily variations

- Humidity levels that affect curing

Harsh climates require thicker concrete, better reinforcement, or special additives to handle the stress. Don’t assume what works in mild climates will work everywhere.

Concrete Strength and Reinforcement

The right concrete mix and reinforcement turn a basic driveway into one that lasts decades. These choices matter as much as getting the thickness right.

Choosing the Right Concrete Mix

Not all concrete is created equal. The PSI rating tells you how much pressure the concrete can handle before it fails.

For most residential driveways, use concrete with at least 3,000 PSI strength. This handles regular car traffic without problems. Heavy-duty applications need 4,000 PSI or higher for trucks, RVs, and commercial use.

Cold climate areas need special attention. Air-entrained concrete contains tiny air bubbles that give water room to expand when it freezes. Without this protection, freeze-thaw cycles will crack your driveway within a few years.

Ask your concrete supplier about:

- PSI rating appropriate for your use

- Air entrainment for freeze protection

- Fiber additives that reduce small cracks

- Water reducers that make stronger concrete

The right mix costs a bit more but prevents expensive repairs later. Don’t compromise on concrete quality to save a few dollars.

Reinforcement Options

Reinforcement helps concrete handle stress and prevents small cracks from becoming big problems. But not every driveway needs it.

Wire mesh works well for standard residential driveways. It’s affordable and easy to install. The mesh distributes loads across a wider area and controls crack formation.

Rebar provides stronger reinforcement for heavy-duty applications.

Use it for:

- Driveways supporting trucks or RVs regularly

- Long driveways over 20 feet

- Areas with poor soil conditions

- Slopes or uneven terrain

Reinforcement becomes necessary when you have heavy loads, weak soils, or harsh climate conditions. It also helps in areas where the concrete spans over soft spots or transitions between different soil types.

Place reinforcement properly for best results. It should sit in the middle third of the concrete thickness, not on the bottom where it won’t help much.

Installation Best Practices for a Durable Driveway

Getting the concrete thickness right is only half the battle. How you prepare and install determines whether your driveway lasts 15 years or 30 years.

Subgrade and Base Preparation

The ground under your concrete needs to be absolutely solid. This step makes or breaks your entire project.

Start by removing all grass, roots, and loose topsoil. Dig down to firm, stable soil that doesn’t move when you walk on it. Soft spots need extra attention or they’ll cause settling later.

Grade the area with proper slope for drainage. Water should flow away from buildings and toward grass areas or storm drains. Even small puddles cause big problems over time.

Add a base layer of crushed stone or gravel:

- Use 4-6 inches of material for most driveways

- Compact in layers no thicker than 4 inches each

- Test compaction by walking on it – no soft spots allowed

- Level the surface before pouring concrete

Don’t skip the compaction step. Loose base material leads to uneven settling and cracks. Rent a plate compactor or hire professionals with proper equipment.

Curing and Joint Placement

Fresh concrete needs time and moisture to reach full strength. Rush this process and you’ll regret it later.

Keep concrete damp for at least 7 days after pouring. Cover with plastic sheeting or spray with water regularly. Hot, windy weather dries concrete too fast and weakens it.

Avoid driving on new concrete for a full week minimum. Heavy vehicles need even longer. The concrete continues gaining strength for weeks after installation.

Expansion joints prevent random cracking by giving concrete room to move.

Place joints:

- Every 10-12 feet in long driveways

- Where the driveway meets sidewalks or garage floors

- At changes in thickness or direction

- Around obstacles like utility boxes

Cut joints within 24 hours of pouring while concrete is still soft. Fill them with flexible sealant to keep water out. Proper joints control where cracks form instead of letting them happen randomly.

Drainage and Water Runoff

Water is concrete’s worst enemy. Poor drainage causes more driveway problems than heavy vehicles or thin concrete combined.

Standing water weakens concrete by soaking into tiny cracks and pores. When this water freezes, it expands and creates bigger cracks. Over time, this cycle destroys even thick, well-built driveways.

Proper slope moves water away quickly before damage occurs. Plan for at least 1/4 inch of fall per foot of driveway length. Direct water toward grass areas, storm drains, or street gutters – never toward your house foundation.

Check drainage during heavy rains to spot problems early. Puddles that last more than a few hours signal trouble spots that need attention.

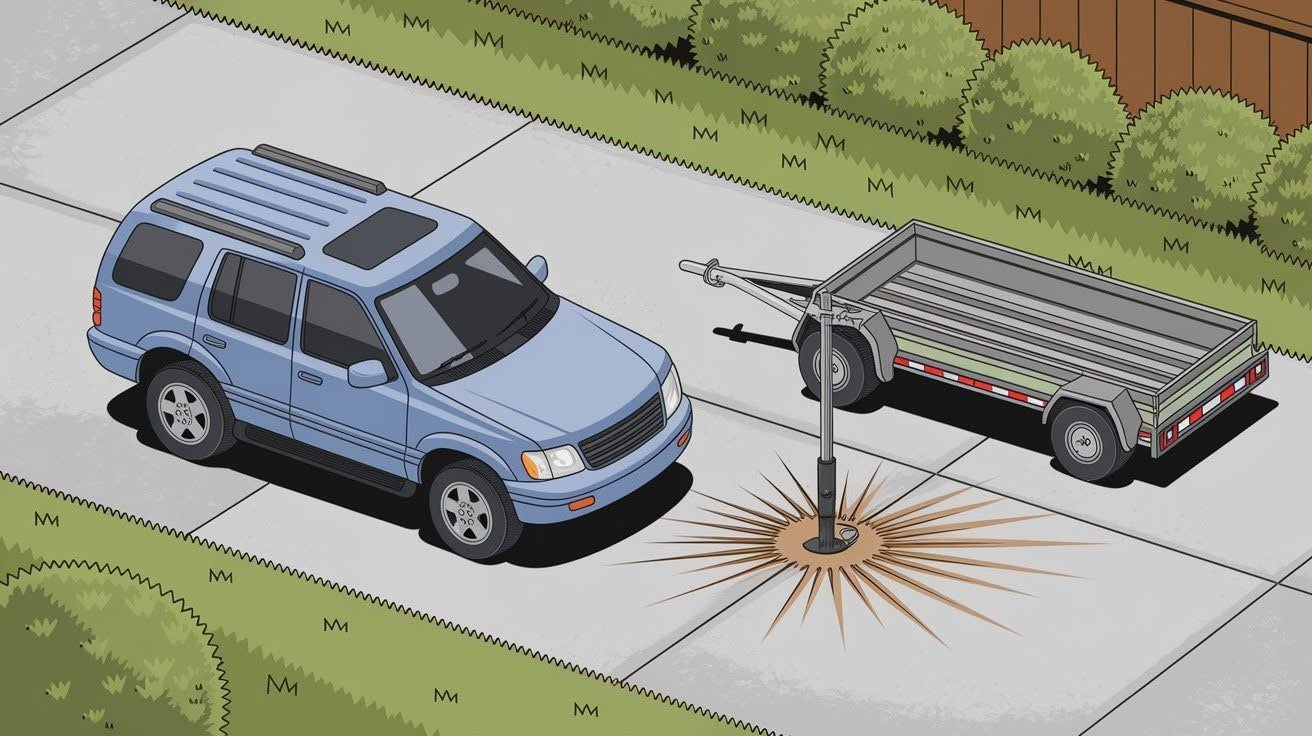

Type of Load Distribution

How weight gets distributed across your driveway affects how much stress the concrete experiences.

Car and truck tires spread weight over a relatively large area. This creates distributed loads that most concrete handles well. Even heavy vehicles work fine when the weight gets spread out properly.

Point loads concentrate weight into small areas and create much higher stress. Heavy equipment with small contact points, motorcycle kickstands, or trailer jacks can punch through concrete that handles trucks just fine.

Consider the worst-case loading your driveway might face. A moving truck with outriggers creates different stress than the family SUV. Plan thickness and reinforcement accordingly.

Quality of Base Preparation

The base under your concrete determines how well loads get distributed to the soil below. A good base spreads stress over a wider area and prevents settling.

Use 4-6 inches of compacted crushed stone or gravel for most driveways. Compact in layers no thicker than 4 inches each. Loose base material allows uneven settling that cracks concrete regardless of thickness.

The base also provides drainage under the slab. Water that can’t drain away creates soft spots and reduces support. Poor base preparation causes more failures than thin concrete or missing reinforcement.

Never pour concrete over grass, loose dirt, or uncompacted fill. Take time to prepare a solid foundation that will support your driveway for decades.

Building Codes and Local Requirements

Most areas have specific rules about driveway construction that affect thickness requirements. These codes exist to ensure safety and durability in your climate and soil conditions.

Some regions require minimum thickness based on local freeze-thaw cycles, soil conditions, or typical vehicle loads. Commercial driveways often have stricter requirements than residential ones.

Check with your local building department before starting work. Some areas require permits for new driveways or major repairs. The permit process helps ensure your project meets all local standards.

Working with codes also protects your investment. Following local requirements means your driveway should perform well in your specific conditions. It also prevents problems if you sell your home later.

Common Mistakes to Avoid

Even experienced contractors make these errors. Learning from their mistakes saves you thousands in repairs and replacements.

Using Too Thin a Slab

Many homeowners try to save money by reducing concrete thickness. This almost always backfires within a few years.

A 3-inch driveway might look fine initially, but it won’t handle normal use for long. Cars create more stress than most people realize, especially when turning or braking hard.

Thin concrete also struggles with temperature changes. It expands and contracts more dramatically, leading to cracks and edge damage. The money you save on concrete gets spent on repairs quickly.

Stick to proper thickness recommendations. The extra concrete cost is minimal compared to tearing out and replacing a failed driveway.

Skipping Reinforcement

Some contractors skip reinforcement to save time and money. This works fine until it doesn’t.

Wire mesh or rebar doesn’t prevent all cracks, but it controls them. Small cracks stay small instead of growing into major problems. Reinforced concrete also handles settling better if the base moves slightly.

Areas with freeze-thaw cycles especially need reinforcement. Temperature changes create stress that plain concrete can’t handle alone.

Don’t let cost concerns talk you out of proper reinforcement. It’s insurance that pays for itself over the driveway’s lifetime.

Pouring Over Poorly Prepared Soil

This mistake causes more driveway failures than any other factor. You can’t build a lasting structure on a weak foundation.

Contractors sometimes skip soil preparation to finish jobs faster. They pour concrete directly over grass, loose dirt, or uncompacted fill material.

The results are predictable:

- Uneven settling creates low spots and drainage problems

- Soft areas cause concrete to crack and break

- Poor compaction leads to complete sections sinking

Proper base preparation takes time but prevents major headaches. Insist on seeing the prepared base before any concrete gets poured. A solid foundation is worth the extra effort and cost.

Here are key tips for a durable concrete driveway

- Use proper thickness for your needs: Standard 4 inches works for cars, but go with 5-6 inches for trucks, RVs, or problem soils that need extra support.

- Choose the right concrete strength: Use at least 3,000 PSI for regular driveways and 4,000 PSI for heavy-duty applications. Cold climates need air-entrained concrete.

- Prepare the base thoroughly: Remove all soft soil, add 4-6 inches of compacted gravel, and ensure proper drainage slope before pouring concrete.

- Add reinforcement when needed: Use wire mesh for standard driveways or rebar for heavy loads, long spans, or poor soil conditions to control cracking.

- Allow proper curing time: Keep concrete damp for 7 days minimum and avoid driving on it during this period for maximum strength development.

- Install expansion joints correctly: Place joints every 10-12 feet and at direction changes to control where cracks form instead of letting them happen randomly.

- Don’t cut corners on critical steps: Proper soil prep, adequate thickness, and quality materials cost more upfront but prevent expensive repairs later.

Conclusion

Building a durable concrete driveway comes down to following proven best practices. Use proper thickness for your vehicle loads, prepare the base thoroughly, choose quality concrete mixes, and allow adequate curing time. Don’t skip reinforcement when conditions call for it.

Always check local building codes before starting your project. Requirements vary by area, and permits may be needed. Consider hiring experienced contractors for complex situations or if you’re unsure about any steps.

Remember this final tip: base your thickness decision on how you actually use your driveway, not just initial cost savings. A family with heavy trucks needs different construction than one with compact cars. Plan for your real-world conditions, and your driveway will serve you well for decades to come.

Frequently Asked Questions

What thickness do I need for a standard residential driveway?

Most home driveways work well with 4 inches of concrete for regular cars and light trucks. Consider 5 inches if you have heavier vehicles, soft soil, or harsh freeze-thaw conditions.

Do I need reinforcement in my concrete driveway?

Use wire mesh for standard residential driveways and rebar for heavy-duty applications or poor soil conditions. Reinforcement controls cracking and extends the driveway’s lifespan significantly.

What concrete strength should I specify for my driveway?

Standard driveways need at least 3,000 PSI concrete strength for regular vehicle traffic. Heavy-duty applications with trucks or RVs require 4,000 PSI or higher for better durability.

How long should I wait before using my new driveway?

Wait at least 7 days before driving cars on fresh concrete to allow proper strength development. Heavy vehicles need longer curing time, and keep the concrete damp during this period.

Why is base preparation so important for driveways?

Poor base preparation causes settling, cracking, and early failure regardless of concrete thickness. Proper grading, compaction, and drainage create the foundation your driveway needs to last decades.